Pros of using optical measurement systems in multi-material inspection processes

Why Optical Dimension Solutions Are Vital for Modern Production Practices

In today's competitive production landscape, you can't afford to overlook the advantages of optical dimension systems. Exactly how specifically do these systems transform making methods, and what implications do they hold for the future?

The Evolution of Optical Measurement Systems in Production

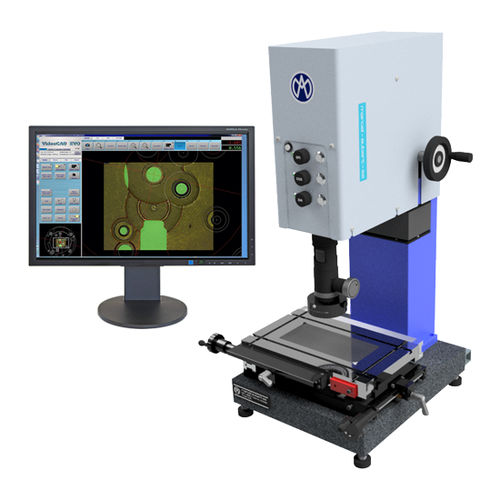

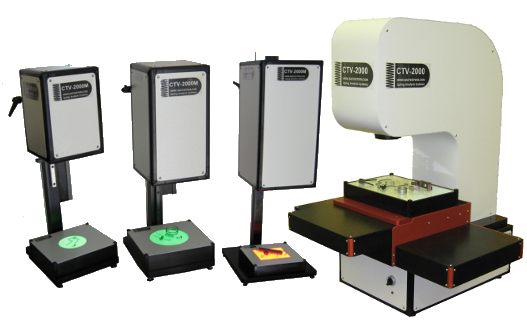

As modern technology swiftly developments, the evolution of optical measurement systems in manufacturing has transformed exactly how industries ensure precision and high quality. You could've noticed that typical dimension methods, like micrometers and calipers, often fall brief in speed and precision. Optical systems become a remedy, leveraging light to record detailed dimensions quickly.

In the past, these systems were limited, mostly used for certain applications. And now, advancements in laser innovation and imaging software enable flexible, real-time analyses across different industries. When carrying out these systems in your procedures., you can anticipate higher accuracy and lowered human error. optical measurement systems.

Additionally, the combination of automated optical assessment tools simplifies quality assurance, letting you concentrate on production efficiency. As the demand for accuracy grows, adjusting to these cutting-edge optical dimension modern technologies will certainly maintain your procedures affordable and trustworthy in a busy market.

Key Advantages of Optical Measurement Technologies

Optical measurement technologies use numerous key advantages that can substantially enhance your production processes. Initially, they give high accuracy and precision, permitting you to make crucial modifications with confidence. This brings about improved product quality and lowered waste, which directly influences your profits.

In addition, these systems are non-contact, meaning you can determine delicate or moving parts without causing damage. This capacity not only secures your products but likewise increases throughput because you can gauge items on the assembly line without disturbance.

Optical systems are frequently quicker than traditional methods, allowing you to collect information rapidly and make timely choices. Their convenience means they can be applied to a large array of geometries and materials, adapting quickly to your details needs. By integrating optical measurement innovations, you're not simply staying on par with sector criteria; you're establishing them.

Applications of Optical Measurement in Various Industries

While numerous sectors are progressively transforming to advanced dimension techniques, the applications of optical dimension systems attract attention due to their unique abilities. In auto manufacturing, you'll locate these systems assisting to assure accurate positioning and surface area quality in components. In aerospace, they're vital for examining complex geometries and guaranteeing the security of critical parts.

In electronics, optical measurement aids in the exact positioning of integrated circuits on circuit card, improving general effectiveness. The clinical tool industry additionally advantages, as these systems enable the meticulous measurement of detailed components, guaranteeing they meet strict governing criteria.

Optical measurement systems are also used in fabrics, where they evaluate textile patterns and imperfections, enhancing top quality. With their adaptability, these systems are changing just how different sectors approach dimension, ultimately driving innovation and efficiency in production processes.

Enhancing Top Quality Control Via Optical Dimension

When it involves quality assurance, precision measurement methods can make all the difference in your manufacturing process. By executing optical dimension systems, you can attain real-time quality assurance that maintains your products reputable and consistent. This not just improves your overall production efficiency yet likewise increases customer satisfaction.

Precision Measurement Techniques

In today's competitive production landscape, implementing precision measurement strategies can greatly improve high quality control procedures. By using sophisticated optical dimension systems, you can attain higher precision and repeatability in your measurements. These techniques enable you to identify even the tiniest variants in item measurements, making certain that every part satisfies strict specifications.

Utilizing devices like laser scanners and optical comparators, you can rapidly assess the top quality of your items, significantly reducing the danger of problems. Furthermore, these systems give real-time information, allowing you to readjust processes promptly, thereby minimizing waste.

Including these accuracy measurement strategies not just enhances product quality yet additionally improves consumer contentment and self-confidence in your brand name. Accept these innovations to preserve an one-upmanship in your production procedures.

Real-Time High Quality Assurance

Optical dimension systems play a vital duty in this process, enabling you to check product top quality continuously. By integrating these systems right into your workflow, you can identify discrepancies from specs nearly instantaneously, reducing the possibilities of issues getting to the market. Ultimately, accepting real-time quality guarantee with optical dimension systems not only improves your result yet also strengthens customer trust fund in your brand.

Decreasing Waste and Improving Effectiveness With Optical Solutions

When you apply optical dimension systems, you'll see a substantial decrease in production mistakes. These systems simplify quality assurance processes, making it easier to recognize and correct issues quickly. Therefore, you not only reduce waste but additionally boost overall efficiency in your production operations.

Minimizing Production Errors

To reduce production errors effectively, suppliers significantly rely upon optical dimension systems that boost precision and reduce waste. These systems offer real-time comments, enabling you to recognize disparities prior to they intensify into pricey blunders. By utilizing exact measurements, you can guarantee that every element satisfies specifications, which substantially reduces the danger of issues. In addition, optical systems can automate numerous procedures, lowering human error and improving operations. You'll locate that implementing these modern technologies not just enhances efficiency however additionally promotes a society of high quality within your group. As you embrace optical measurement systems, you'll notice a significant decrease in rework and scrap prices, ultimately resulting in extra reliable production techniques and enhanced fundamental results.

Enhancing Quality Assurance

By taking on optical dimension systems, you're not just decreasing manufacturing mistakes yet additionally simplifying top quality control. These systems provide real-time feedback, permitting you to detect defects before they escalate. Rather pop over to this web-site than counting on manual examinations, which can be susceptible and time-consuming to human error, you can automate the procedure. This quicken manufacturing and assurances consistency across sets. With specific dimensions, you can determine variations in processes or materials promptly, lowering waste and enhancing overall efficiency. In addition, incorporating optical systems helps you maintain conformity with market standards, offering you an affordable edge. Inevitably, purchasing optical measurement modern technology improves your quality control, leading to far better products and completely satisfied consumers.

Integrating Optical Dimension Systems Into Existing Processes

Next, choose the right optical measurement technology that aligns with your production needs. Consider factors like the size of the parts, called for accuracy, and combination abilities with existing devices. Training your staff on the new technology is essential; they need to feel certain utilizing it to optimize its benefits.

Finally, keep track of the integration procedure very closely. Gather data on performance improvements and recognize any type of difficulties at an check this early stage. This proactive approach warranties not just a smooth shift but additionally an enduring effect on your manufacturing performance and item quality.

The Future of Optical Dimension in Production

As you accept optical dimension systems in your manufacturing procedures, it's important to look ahead and take into consideration how these modern technologies will develop. Future innovations promise boosted precision and speed, allowing real-time responses that can drastically lower production errors (optical measurement).

Moreover, miniaturization of optical sensors will certainly make them extra versatile, fitting right into tighter rooms and various applications. The rise of automation will likewise boost their capabilities, as automated systems will use these dimensions to maximize manufacturing flows perfectly.

As you adjust to these modifications, remaining educated concerning emerging technologies will be vital. By purchasing innovative optical dimension remedies, you'll place your production procedures for lasting success and performance. Welcome the future; it's intense for those that introduce!

Regularly Asked Inquiries

Just How Do Optical Dimension Solutions Contrast to Standard Measurement Techniques?

Optical useful reference measurement systems provide higher performance, rate, and accuracy compared to traditional approaches - optical measurement. You'll locate they minimize human error and enhance information collection, making your dimensions much more dependable and improving total efficiency in your processes

What Are the Initial Prices of Carrying Out Optical Measurement Equipments?

You'll locate the preliminary costs of applying optical measurement systems can be significant, usually including equipment software application, training, and purchase. Nonetheless, these investments typically bring about greater performance and accuracy over time.

Are There Certain Training Requirements for Utilizing Optical Measurement Systems?

Yes, you'll need particular training to use optical measurement systems successfully. Familiarizing yourself with the dimension, software program, and equipment methods is crucial. Manufacturers commonly give training programs to guarantee you're positive and qualified in utilizing these systems.

Can Optical Dimension Equipments Be Customized for Distinct Manufacturing Requirements?

Yes, you can personalize optical dimension systems to fulfill your specific manufacturing needs. By adjusting specifications and integrating special functions, these systems can boost accuracy, flexibility, and performance, ensuring they align perfectly with your manufacturing needs.

What Upkeep Is Needed for Optical Measurement Systems?

You'll need to regularly clean the optics, adjust the system, and look for software application updates. Checking efficiency and dealing with any wear or tear promptly assures your optical dimension systems work accurately and reliably with time.

Verdict

In today's hectic manufacturing globe, welcoming optical measurement systems is vital for remaining affordable. These technologies not just improve precision and rate however also boost quality assurance and decrease waste. By incorporating these sophisticated services right into your procedures, you'll foster a society of dependability and customer contentment. As you seek to the future, purchasing optical dimension will assure your operations continue to be compliant and reliable, positioning your organization for continued success in the ever-evolving landscape.

As modern technology quickly breakthroughs, the evolution of optical dimension systems in production has transformed just how industries ensure accuracy and high quality.While lots of industries are progressively transforming to innovative measurement methods, the applications of optical dimension systems stand out due to their unique abilities. By using innovative optical measurement systems, you can achieve higher precision and repeatability in your dimensions. Optical dimension systems play an important function in this procedure, permitting you to monitor product high quality constantly. Just How Do Optical Dimension Systems Compare to Conventional Measurement Techniques?